SGP celebrates the go ahead of one of the UK’s largest Gigafactories in Coventry

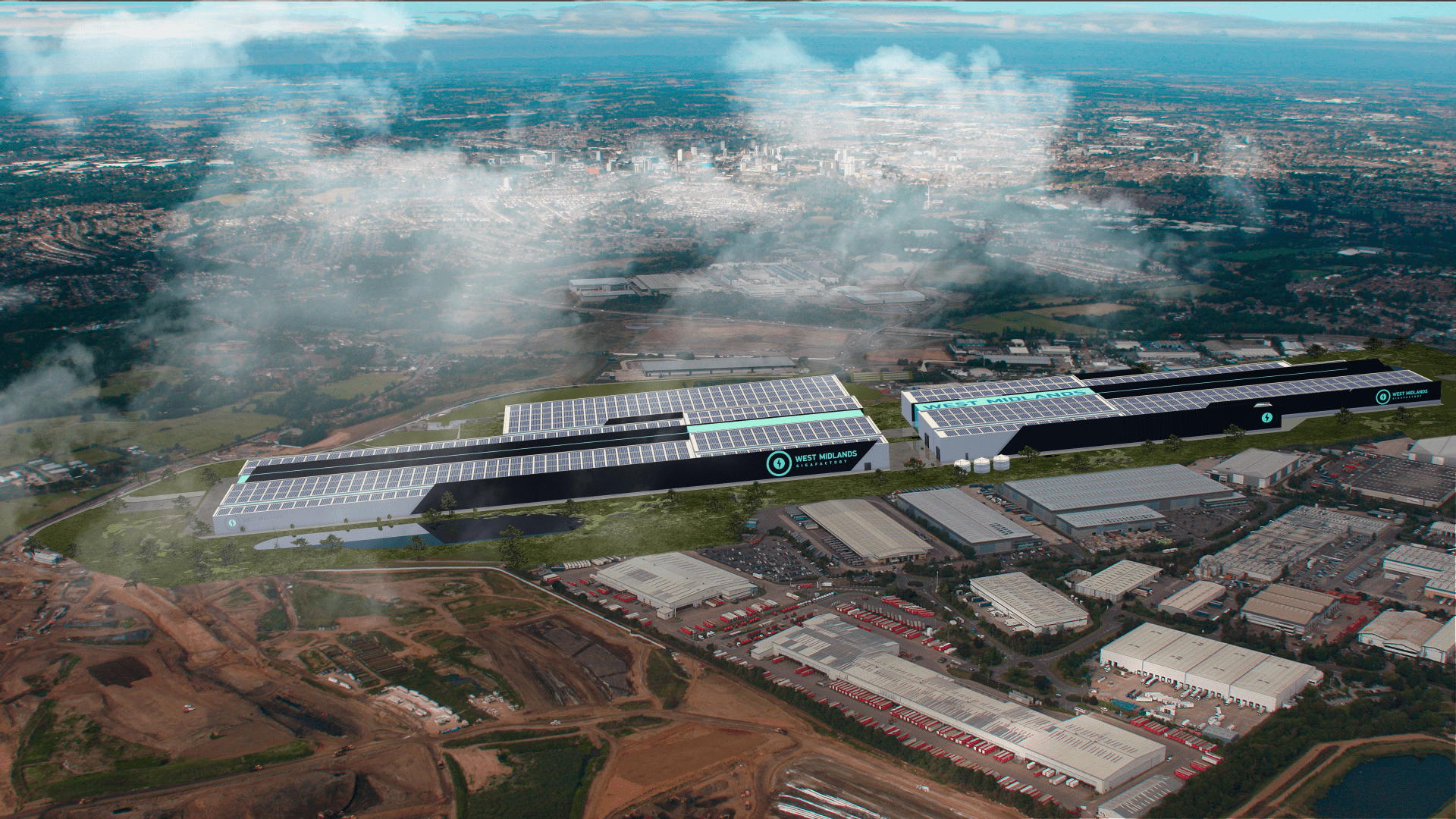

Stephen George + Partners LLP (SGP) is celebrating the go ahead of £2.5 billion, 5.7 million sqft “cradle to cradle” Gigafactory (electric vehicle battery manufacturing facility) in Coventry. Working closely with the West Midlands Gigafactory joint venture team, SGP has formulated outline plans for one of the largest Gigafactory’s in the UK.

Explains Kenny Leadbeater, Associate at SGP: “The West Midlands Gigafactory joint venture’s ambition is to create an international scale manufacturing facility, capable of producing up to 60 Gigawatt hours per annum of battery output. We designed a “cradle to cradle” facility, enabling the development of a vertically integrated battery production operation which includes the preparation of Pre-cursor Cathode Active Material (PCAM), the production of Cathode Active Material (CAM) and a battery recycling operation which reflects the growing need to re-use battery chemicals and components to minimise waste.”

Having extensively researched other Gigafactories worldwide, SGP has developed an indicative layout of two buildings of 2 and 3.5 million sqft, which can be built in phases.

Expected to create 6,000 skilled jobs at the plant alone, the 309 hectare site sits in the heart of the UK motor manufacturing industry, with most vehicle manufacturers within a two hour road journey. The locality is already home to world-leading research in battery technology and production with the UK Battery & Industrialisation Centre (UKBIC), as well as a highly skilled labour force.

Concludes Kenny: “This is an incredibly exciting project, of national and international significance. Being one of the largest single Lithium Ion (LI) battery manufacturing operations in the UK, it will have a transformational impact on advanced manufacturing in Coventry and Warwickshire and help UK manufacturing deliver the transition to electric vehicles (2030) and the wider process of delivering alternatives to fossil fuel power.”

The site can be production ready from 2025.

- X

- Share on LinkedIn

- Copy link Copied to clipboard